Johanna Lehto, Mechanic and Inspector

From the hospital operating room to fighter jet engine technician

Johanna originally trained as a nurse and worked for ten years in a university hospital’s emergency surgery unit. She wanted to switch from a female-dominated, low-paid field to another line of work and enrolled in aircraft mechanic training at Tredu, Tampere Region Vocational College.

4

years at Patria

Mechanic and Inspector

Aircraft Mechanic studies in Tredu, Tampere Region Vocational College

Outdoor activities

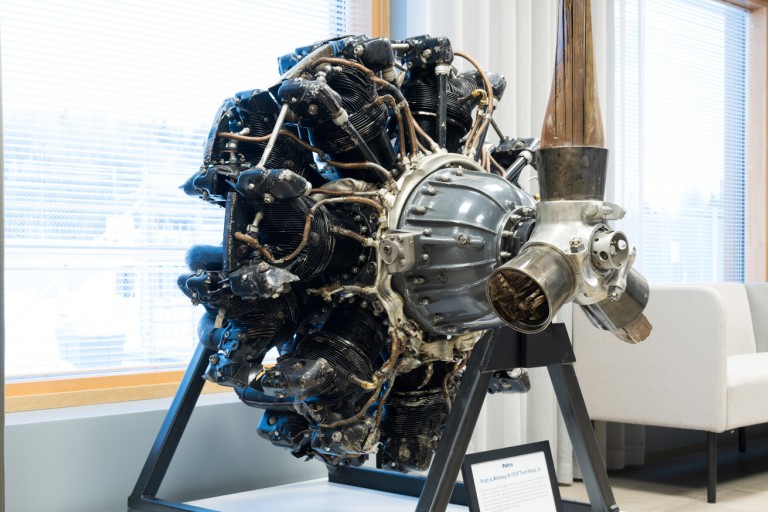

Johanna Lehto’s journey from hospital operating rooms to precision engine repairs at Patria. The precision required to repair fighter jet engines at Patria suits Johanna perfectly. She was already familiar with responsible work from her previous job in a hospital operating room.

What do a hospital operating room and a fighter jet engine workshop have in common? Johanna, who has years of experience in both environments, knows the answer first-hand.

– In both jobs, extreme accuracy and careful attention are required. In hospital, it’s about people’s health; in engine repairs, it’s about flight safety, she summarises.

Johanna originally trained as a nurse and worked for ten years in a university hospital’s emergency surgery unit. She wanted to switch from a female-dominated, low-paid field to another line of work and enrolled in aircraft mechanic training at Tredu, Tampere Region Vocational College.

Hornet engines are the team’s responsibility

Johanna found both her work placement and later her permanent position at Patria’s production unit in Linnavuori, Nokia, where aircraft engines are repaired and maintained.

According to her, there are several similarities with her previous career. Both surgery and engine repairs involve extensive use of specialised technical instruments.

– Another connecting factor is the careful management of risks. Human error can happen to anyone, but it can be minimised with precise work instructions and checks. It’s also important to monitor and recognise your own alertness.

At Patria, Johanna applies meticulous precision and risk management to the inspection and repair of fighter jet engines.

At Patria, Johanna works in a team responsible for tasks related to the Finnish Air Force’s Hornet F/A-18 jet engines. When an engine arrives in Linnavuori, it is dismantled into modules. Johanna is responsible for inspecting and repairing the low-pressure compressor.

After the necessary procedures, the disassembled compressor is reassembled and moved to assembly, where the modules are put back together.

The job demands good teamwork and the ability to manage the whole process

In addition to her role as a technician, Johanna acts as an inspector, responsible for checking and delivering repaired modules on schedule. The work requires systematic organisation, as repairing a single module involves various steps carried out by professionals from different fields. For instance, the low-pressure compressor module goes through washing and crack inspection, handled by specialists.

– The work sometimes feels like juggling, with several balls in the air at once. You need to be able to prioritise tasks so that everything progresses in the right order along the timeline. The job demands a good grasp of the bigger picture and collaboration – you can’t just focus on your own little area, Johanna emphasises.

Combining work and family life works well

Within four years, Johanna has advanced from technician to inspector, even though she spent one and a half years on parental leave during that time.

– My supervisor has recognised my strengths as an employee and wants to make the most of them at work. I believe there will be further opportunities for career development at Patria in the future.

The repair industry has traditionally been male-dominated, but more women are now being seen in technician roles at Patria.

– The reception has been really good, and we newer employees have also received great support from the more experienced veterans. We have a good work community where colleagues help each other out, Johanna says appreciatively.

Johanna’s journey at Patria highlights her rapid career growth, supportive work environment, and successful balance between professional and family life.

Combining work and family life is also smooth at Patria. Johanna’s family enjoys spending a lot of time outdoors together. Their companions for outdoor activities are two mixed-breed dogs. There’s plenty of energy, as one is a Finnish hound and Lapponian herder mix, while the other’s parents are Irish and English setters.

Text: Matti Remes