In helicopter airframe maintenance, Patria serves customers all around the world, including military and governmental organizations as well as civil customers.

"Our customer base in helicopter airframe maintenance is wide and global - from Greenland to Japan."

Patria delivers helicopter airframe maintenance services from our own locations in Sweden, Norway and Finland, and when agreed, on customer locations and through mobile field teams. For mobile support we can deploy technicians and engineers that can assist both in line and base maintenance.

Scheduled and unscheduled maintenance and repairs

Annual and major inspections, including for example:

- Corrosion Inspections and repairs

- Rotor Blade inspections and repairs

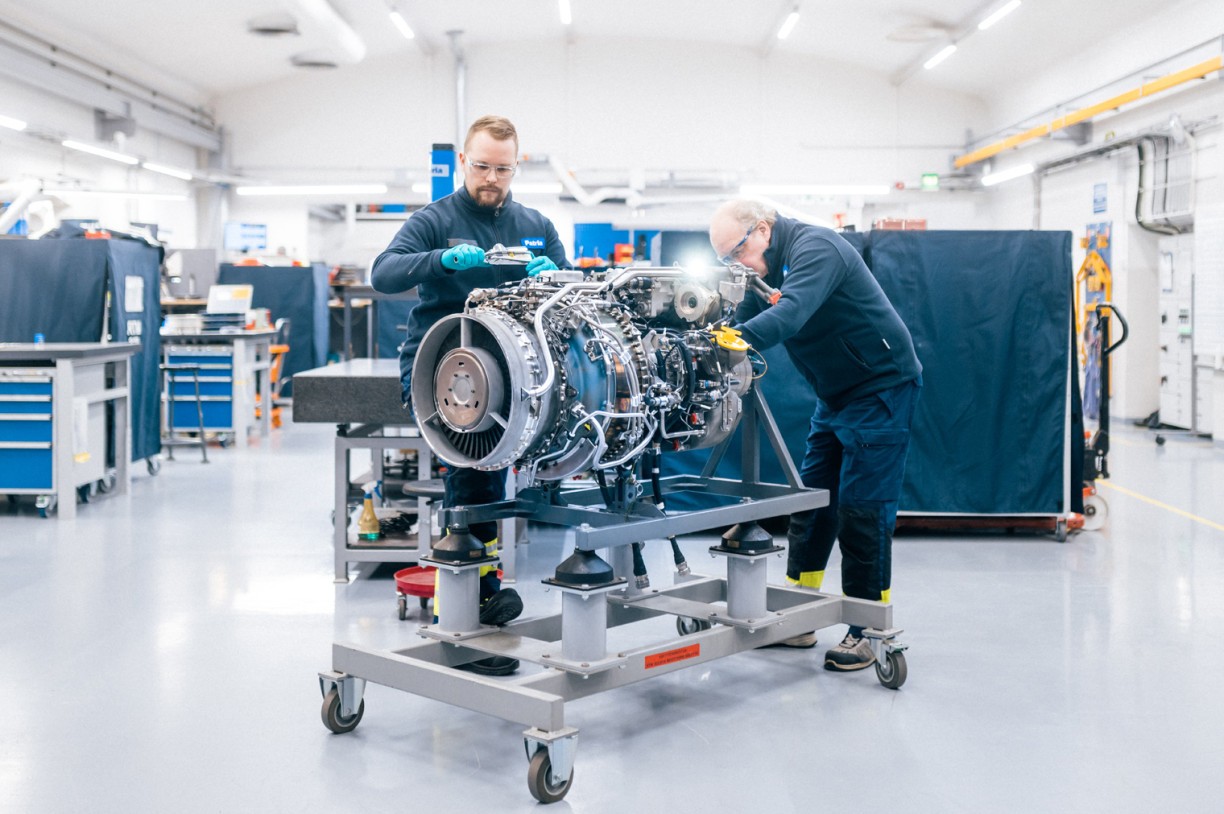

- Engine Inspections, including borescope inspections

- Incident and accident inspections with repairs and rebuild

Repair work

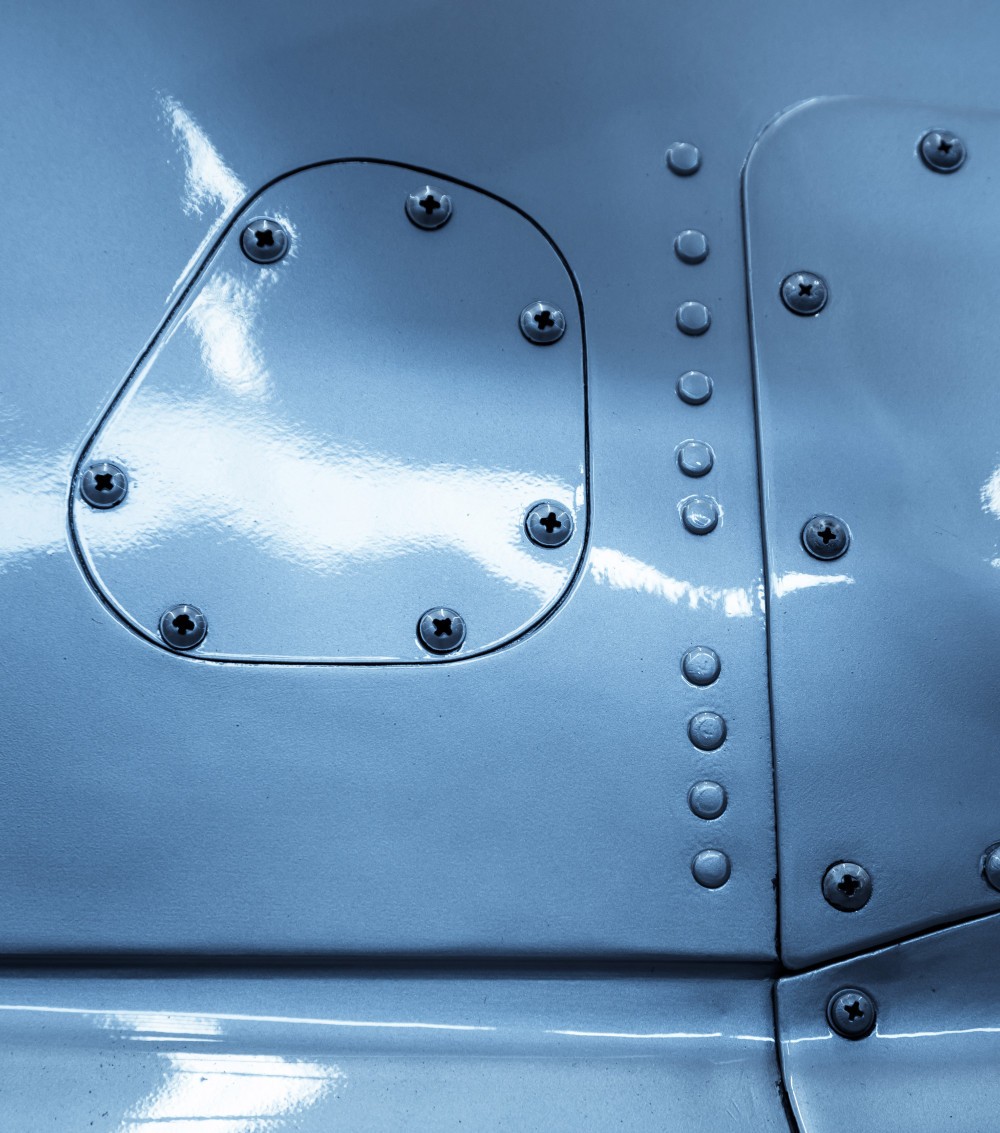

- Airframe, fuselage and tail boom repair (including rebuilding, repairs and upgrades using OEM approved fixtures and jigs – Bell/AW206, 204, 205, 212, 412, 214)

- Alodine treatment

- Composite repair

- Structural repair work

- Sheet metal work

- Welding

Modifications, installations and upgrades

- Installation and customisation of optional equipment

- System integration of equipment, such as HEMS installation, avionics, etc.

- Rewiring of complete airframes

- Laser markings for wiring cables

- Interior work and interior refurbishment

- Customising and refurbishment

- Painting of complete helicopter airframes

- Engineering and engineering assessments