Patria is one of the founding members of FAME, an ecosystem that promotes 3D printing

22.12.2020

The companies and higher education institutions in the FAME ecosystem are aiming to make Finland one of the leading countries in 3D printing expertise, utilisation and sales. As one of the founding members, Patria is actively involved in these development efforts, which are based on openly sharing data and experiences.

Text: Päivi Brink Photos: FAME material bank

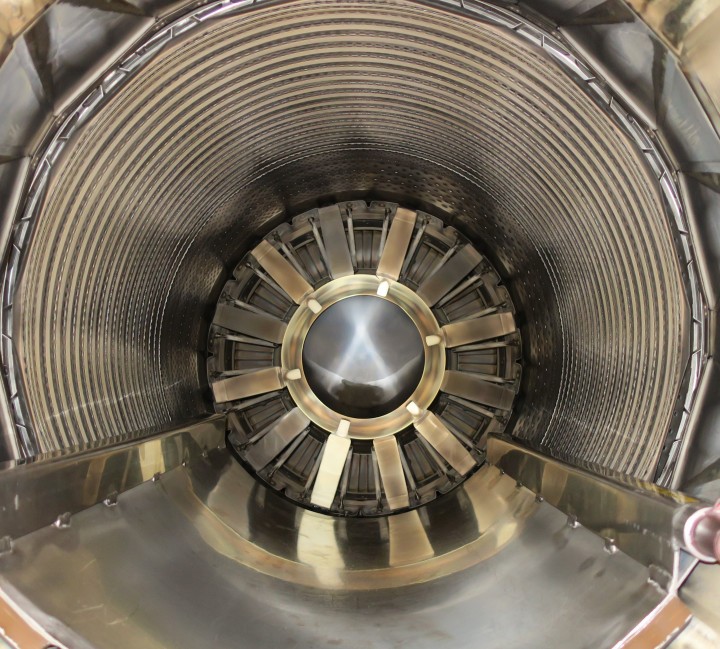

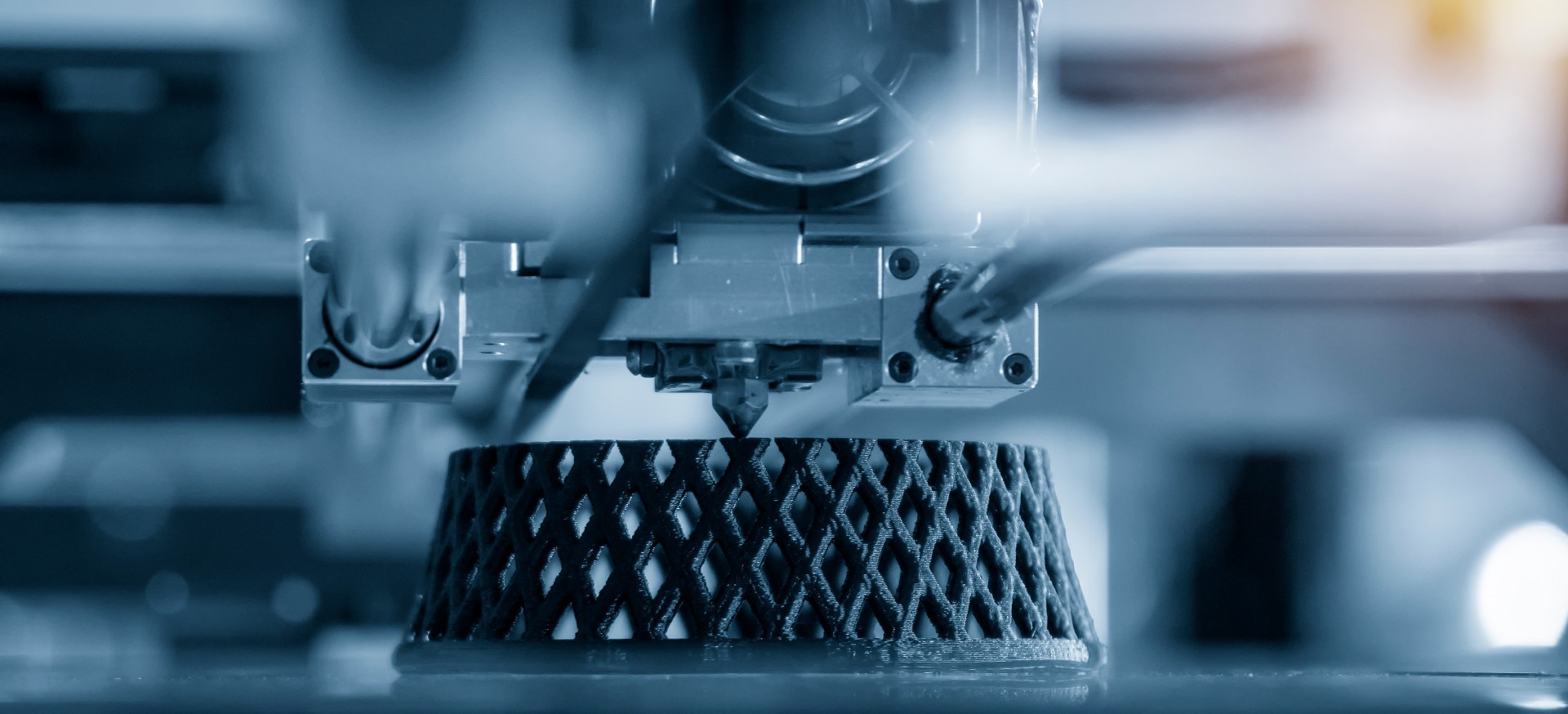

DIMECC Oy (the leading innovation platform in Finnish industrial manufacturing) launched FAME in late 2020 to provide an ecosystem in which Finnish companies and higher education institutions could work together to develop 3D printing. FAME is an acronym of the Finnish Additive Manufacturing Ecosystem. 3D printing is considered to be additive manufacturing, as the process involves adding thin layers of raw material to a part until it acquires the desired form.

FAME brings together a wide range of Finnish expertise in 3D printing from different-sized companies that specialise in industrial manufacturing. FAME’s founding members are: k3D-Step, 3D Formtech, Andritz, CITEC, DBE Core, Delva, Elomatic, EOS Finland, Etteplan, Huld, Lillbacka Powerco, MiniFactory, Origo Engineering, Patria, Raute, Vossi and Wärtsilä. All kinds of different companies are welcome to join this open ecosystem.

Where academic and corporate R&D meet

As a result of collaboration with institutions of higher education, a 3D printing test centre is being established at the Smart Technology Hub in Vaasa, and LUT University in Lappeenranta is launching a degree programme in modular 3D printing all the way from bachelor to doctoral level.

“Collaboration between companies is possible because we’re on the interface with research and business. The closer you get to actual products, then the more closely companies will guard their expertise. This kind of cooperation – that is, engaging in product development within a network – is new for Patria, and we need to learn to be more open within the constraints placed upon us by the defence, security and aviation sectors. Data protection regulations are important and must be complied with, but there are plenty of things that we can share with others. FAME also enables external public funding for development work,” says Pasi Niinikoski, the Patria Group’s Chief Business Development Officer.

It was important for Patria to be involved in FAME from the outset. The Vice Chair of FAME’s Board of Directors is Sakari Pasanen, Director, Business Development at Patria Aerostructures.

“By getting involved in FAME cooperation from the outset, we seized an opportunity to make rapid advancements and made sure that Patria would be able to have its say. In this community, Patria represents major high-tech industrial companies and, as Vice Chair, I’m able to raise issues that are important to us. Although we’re the only defence-sector company in the network, the multidisciplinary nature of our business enables us to bring a wide range of perspectives to the application of 3D printing. 3D technology is being developed in both the defence industry and the civilian sector, and we’re ready to apply it in our own field,” says Pasanen.

He stresses the importance of new perspectives in development work.

“The greatest advantage of carrying out development work in a network is being able to adopt new ways of working and exchange experiences about all kinds of developmental efforts. This will hopefully help us to see brand-new solutions for our applications – the kind that we wouldn’t have been able to implement using traditional methods. As part of the ecosystem, we’ll be analysing others’ expertise and are ready to learn from them – and we’re happy to bring our own expertise to the table in return. We’ll also be able to influence the planning of educational content at institutions of higher education to better meet corporate needs,” says Pasanen.

Patria companies widely involved

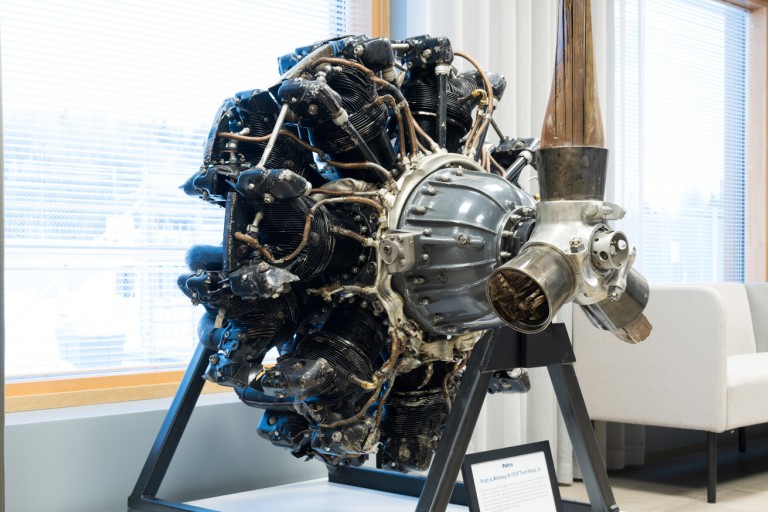

The Patria companies currently involved in FAME collaboration are Millog, Aviation and Land – that is, the majority of Patria. Results and experiences will also be utilised in the HX project and Patria's foreign units.

Millog maintains the Finnish Defence Forces’ army and navy fleets and air force surveillance systems. Spare parts must be available for maintenance and repair under all circumstances, and 3D printing may play a key role in this in the future. FAME could also provide new perspectives on solutions for exceptional circumstances.

“3D printing enables spare parts to be printed on demand regardless of where production is located. Millog has comprehensive expertise and an extensive local network of locations in Finland. I think it’s essential that each FAME company can effectively focus its resources on developing and maintaining its own core business, while collaboration broadens the scope for the development and sale of new service products,” says Millog’s Development Director Antti Salonen.

Millog already has experience and expertise in other areas of digital development via collaboration with several different actors.

“3D printing will bring new opportunities for smart maintenance, and we’re exchanging information and experiences to help us develop new products and services for our own sector,” says Salonen.

Ambitious goals

The companies in the FAME ecosystem are aiming to acquire 5 per cent of the global market volume in 3D printing by 2030.

“We’re talking about the future of the entire manufacturing industry in Finland. Major companies operate globally, and 3D brings production close to customers. If Finland significantly enhances its 3D expertise, this will open up many new opportunities in international markets. Companies will be able to harness the achievements of joint development according to their own strengths,” says Niinikoski.

Network cooperation will also give Patria the opportunity to clarify Patria’s image.

“We’ll also be highlighting some of our lesser-known expertise. We’ll be learning about others’ strengths and telling them about our own,” says Niinikoski.

What did you like about the article?

Thank you for your opinion! You can share the article on social media using the buttons below: