Patria seeks to enhance competitiveness with 3D printing

14.6.2022

Patria is actively involved in an ecosystem that is driving the uptake of additive manufacturing – that is, 3D printing – in Finnish industry. This also opens up new opportunities for Patria.

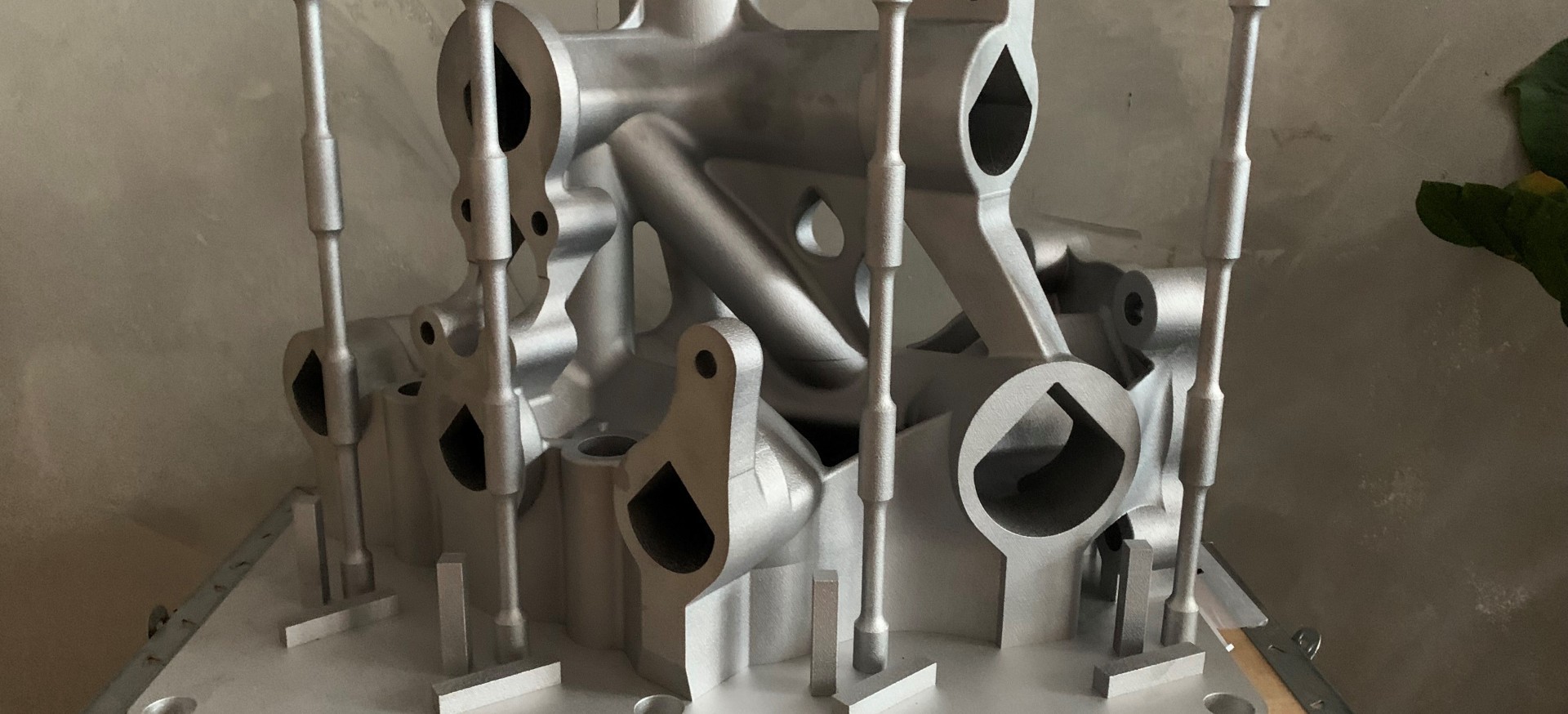

Part in the picture: Design by Francesco Trevisa according to Wärtsilän geometry, AM manufacturing AMEXCI

Text: Matti Remes Photo: Markus Korpela

Additive manufacturing (AM) – also known as 3D printing – is a fast-evolving technology.

Mika Mustakangas, Technology Development Manager at Patria, says that it is vital for the competitiveness of Finnish industry to keep up with the development of new materials and technologies.

AM is one of these.

To this end, companies and universities have established FAME – the Finnish Additive Manufacturing Ecosystem. FAME seeks to elevate Finland to the ranks of the world’s leading countries in 3D printing utilisation, sale and expertise.

“As one of the founding members, Patria is actively involved in these development efforts, which are based on openly sharing data and experiences,” says Mustakangas.

A major project on the global scale

AM technology adds thin layers of raw material to the piece being worked on until the desired shape and structure have been achieved. Manufacturing can employ materials such as metals and plastics.

FAME is currently engaged in a major project to obtain reliable information about the characteristics of different materials when utilising typical AM methods.

Mustakangas says that this project, DREAMS RDI, represents a major effort – even in global terms – as it will create a materials bank of around 10,000 test pieces. Business Finland is funding this two-year project with six million euros.

“The information collected in this project will help the participants to utilise a range of materials and methods in demanding applications, such as when good fatigue resistance is required.

The DREAMS project is engaging in cooperation in many topics. The aim is that the participants will share what they have learned.

“Each of the participants has its own research and development focuses – but we expect that many of the problems will be solved through cooperation between companies and universities. Universities play a significant role in research and testing.

New applications at Patria, too

The DREAMS project does not cover actual new applications and products. Those are created at companies.

AM is opening up a growing number of new applications for Patria’s products and services as well.

“It can be utilised to implement many kinds of entirely new structures. This will yield new product features and characteristics that wouldn’t have been possible in the past.

“Of course, this requires understanding and internalising the possibilities of the new methods. We also have to know how to apply them in both design and actual construction in the industrial manufacturing chain,” says Mustakangas.

Additive manufacturing methods can be used to make spare parts that are difficult to obtain for one reason or another or which must be customised for their application. This also improves security of supply.

Furthermore, AM methods can boost the efficiency of materials use in manufacturing compared to machining, for instance. Reducing material waste not only conserves natural resources but can also achieve major cost-savings and shorter delivery times.

Mustakangas says that the use of AM technology is already quite common in the manufacture of models and customised tools at different Patria units.

“AM is gradually being introduced in products and applications. It’s currently used for the production of small series in some projects.”

Patria intends to stay at the forefront of development

Mustakangas expects that in the long run, AM technology will be one method among many in the manufacturing toolkit.

“Traditional methods won’t disappear from industry – instead, AM is introducing new capabilities to supplement them. In future, parts produced with AM will be found in many very different kinds of products and applications.

According to Mustakangas, AM is a relatively new method and as such still requires plenty of development. Introducing it in industrial use also involves challenges. That said, it is essential to quickly learn how to effectively harness this method and the opportunities it provides.

Patria’s FAME RDI project – which is linked to DREAMS – seeks to study the feasibility of AM in the case of demanding metal structures and other materials. Mustakangas says that the actual application of AM in the development of different products is part of ordinary operational design work.

“Patria must boldly embrace new technologies and be at the cutting edge of development. We must not ‘freeze under fire’ by sticking to our existing products and technologies – the development of this technology is gathering momentum around the world.”

Mustakangas expects that practically everyone in the technology sector will harness the benefits and opportunities of AM in the future.

“I think the question is whether we can make future-compatible products better and more efficiently than our competitors.”

What did you like about the article?

Thank you for your opinion! You can share the article on social media using the buttons below: