Case KTO Rosomak, Poland

Case: KTO Rosomak, Poland

2002-2004 Choosing the best vehicle, Pre-series, Launching the project

A tender for the supply of KTO Rosomak for the Polish Army was won by Patria & Rosomak S.A. formerly known as WZM S.A. Teamed with weapons platform manufacturer OTO Melara. The winning consortium faced fierce competition from defence industry giants. All the competing vehicles went through a demand-ing test phase including over 2700 kilometers of variable Polish soil, vehicles amphibious capabilities and weapons platforms were also tested in extreme conditions. “Tender for the transporters was a real battle between the largest corporations in the world of armaments”1, states former Deputy Minister of National Defence Janusz Zemke, who was also in charge of tender’s evaluation.

The original agreement for 690 vehicles in ten versions was signed. Small pre-series was made in Finland and main series production locally in Poland. Deliveries were planned to take place between 2004 and 2013. Po-land’s Ministry of Defence structured the contract to ensure high share of component supply and work for the domestic companies. Localization of the product was called “Polonization” and it was to become efficiently executed.

In year 2003 Patria Technology Transfer Poland project was launched. This included transfer of manufacturing data and know-how to Rosomak S.A. and its workers. The production facilities in Siemianowice were completely modernized to meet the highest industry quality standards. Newspaper headlines stated: “How did such a tiny plant, like WZM in Siemianowice dare to undertake such a big deal?”. It is true that Rosomak S.A. (WZM S.A.) was not an industry giant at the time but the company has showed remarkable capacity to adopt new technology, skills and talent. Patria’s Technology Transfer and expertise has supported Rosomak S.A. to raise to the high ranks of the Polish defence industry.

2005-2008 Modernization the production, Action based testing

The first Polish made Rosomak IFV from Siemianowice was handed over to the Polish Armed Forces and the Patria Technology Transfer project was finalized. Patria AMV 8x8 manufacturing technology was transferred to Rosomak S.A. The Technology Transfer to Rosomak S.A. was extensive since the company did not have previous experience of modern vehicle production. Entire vehicle production capability was transferred, and Polish industry has been widely utilized for parts and sub-assembly production for the Polish AMV vehicle.

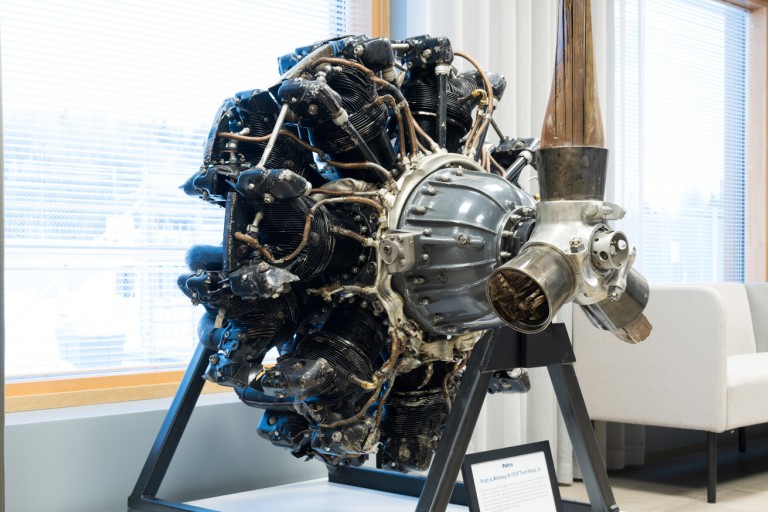

Multiple sub-contractor agreements were formed. These contracts proved to be valuable. Today many of these companies are instrumental suppliers of components to Rosomak vehicles. For example, the chassis and chassis parts were contracted to Komas, Iskra was to provide the bearings, Lotos Oil provided lubricants and fuel, radios and other communication equipment came from Radmor, 12.7 machine guns were supplied by Mechanical Works Tarnow. Scania Poland supplies the engines, hydraulics and pneumatics come from Bosch Rexroth Poland. Stomil in Poznan was to deliver the tire sets and Borimex winches. Darekon selected to supply the dashboard’s for Rosomaks. WZM concluded an agreement with MoD for a prototype of “Afghan” version of Rosomak.

The first batch of Rosomak vehicles arrived to Ghazni, the Polish military base in Afghanistan. Safety of Polish soldiers was prioritized and Ministry of Defence ordered a special “Afghan” variant of the Rosomak vehicle. Poland’s Contribution to the ISAF operation. Polish engagement to ISAF Afghanistan operation consisted of over 130 Rosomak vehicles, all supplied by the Siemianowice plant. It is notable that Rosomak S.A. was also in charge of the logistic support and maintenance of the Rosomak fleet in Afganistan, during the years this has involved in thousands of military and maintenance personnel. This is a practical example that demonstrates how Patria technology and strong local commitment contributes to the national Security of Supply.

2009-2012 Polonization, Variant used in Afghanistan, Chad and Central African Republic

Important milestone of the “Polonization” project was achieved when armored steel plates of Rosomak-vehicle were “Polonized”. The steel was provided by HSJ in Stalowa Wola. By 2009 hundreds of Rosomaks were in constant use in Afghanistan, Chad and Central African Republic. Hundreds of experienced profes-sionals working for Rosomak S.A. worked in rugged environments keeping the Rosomaks running and pro-tecting Polish soldiers.

Rosomak “Afghan” variant was upgraded and this upgrade was based on field experience. Folded mesh screens were added to the sides to provide additional protection against the RPG’s. More field based practi-cal upgrades were also added, including PNK-B observation device to enhance drivers view and situational awareness.

2013-2017 Impacts on employment, Extended agreement, Ongoing cooperation

A set of agreements signed between Rosomak S.A. and Patria to extent the production of the KTO Rosomak in Poland with 200 more vehicle units in different variants. Polonization was deepened further as “the per-centage of the Transporter in 2012 was 94 percent in terms of value”. This was achieved with over 120 local companies involved in the supply chain. According to Minister of Defence Mr. Siemoniak, “Rosomak vehicle production employed a total of about 3500 people within WZM S.A. and cooperative companies”.

Rosomak S.A. has become a synonym for quality, therefore Patria ordered dozens of AMV units from Rosomak S.A. to be exported to Arab Emirates. Components for the assembly were provided by Polish supply chains as used by Rosomak S.A., including Fortaco/Komas and Darekon. The original sub-contractors have become trusted suppliers of subframe parts and complete subframes.

Serial production at Siemianowice factory is running and up until 2022. Poland will have up to 900 Rosomak vehicles in a several versions by 2023. The Patria Technology Transfer was concluded in 2005 but production and strong co-operation between Patria and Rosomak S.A. is active and ongoing.